- HR@aerogentek.com

- +1 (217) 465-6500

Our highly-experienced workforce is capable in CNC machining, laser cutting, welding, complex forming and vacuum heat-treatment.

Sheet metal components with basic to complex profiles Economical tooling solutions versus form dies.

Materials: Hastelloy, Inconel and Stainless

Capability Strength: Up to 40” in diameter Up to .250” thick

Equipment:

Tight tolerance requirements for trimming and hole drilling Hole drilling on entrance and exit sides of coating surfaces.

Materials: Hastelloy, Inconel and Stainless

Capability Strength: Percussion Drilling Precision drilling thru coatings with hole profiles NADCAP certified.

Equipment:

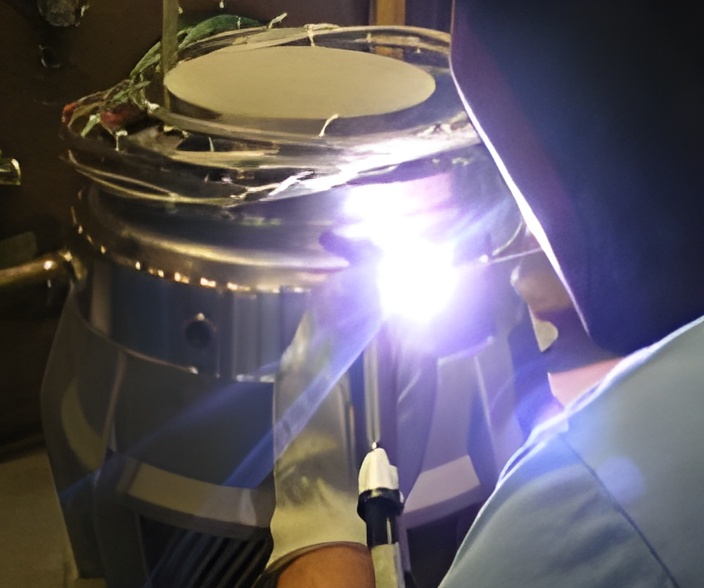

Most Aero and Power Generation market type materials with certified welding requirements.

Materials: Hastelloy, Inconel and Stainless and Aluminum

Capability Strength: 6G Certified Welders Complex welds on both thin and thick gages of materials NADCAP certified.

Equipment:

Most Aero and Power Generation market type materials with certified welding requirement.

Materials: Hastelloy, Inconel and Stainless

Capability Strength: Complex Welds and locations on both thin and thick gages of materials NADCAP certified.

Equipment:

AeroGen-TEK is a leading provider of highly-complex components

for the Aerospace and Industrial Gas Turbine Markets.

Cage Code: 88R12

FAA Repair Facility

Classified Small Business

Email us at HR@aerogentek.com

2121 South Main St. Paris, IL 61944